|

|---|

All records came off the press with the standard sized spindle hole. If a modern 7-inch record is supposed to have the large 45 RPM spindle hole or an optional push-out center, this is automatically punched into the record as it comes out of the press. Since all compression moulded records will have extra material around the outer edge, this is also trimmed at that time. (Injection moulded records have a properly formed outer edge when they are pressed.)

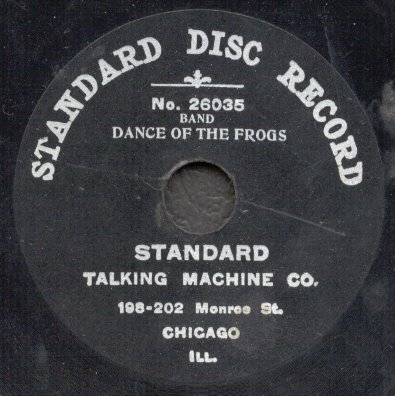

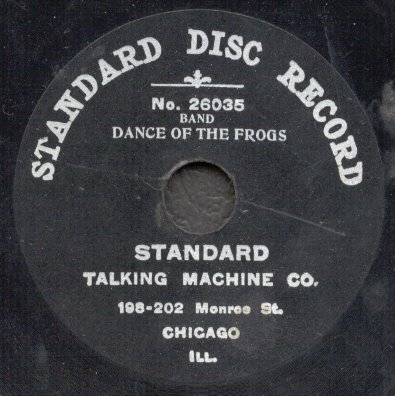

The larger holes for Standard, United, Harmony, Aeretino, etc, were drilled out in their individual factories. Tim Fabrizio did the research on these companies for an ARSC talk about 15 years ago.

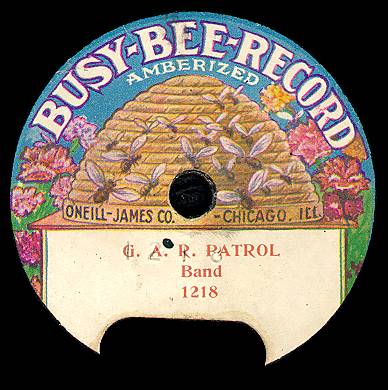

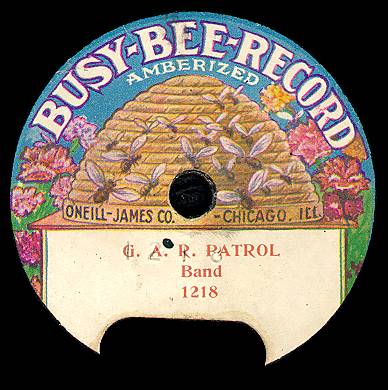

Some English Columbias from the '30s had polygonal shaped spindle holes! Don't forget the litttle Berliner discs of 1889 (3.2" in diameter) which had a key-hole shaped spindle hole to prevent slippage. Busy-Bee offered a standard sized hole and an additional large "race track" hole. Of course they sold players that fit that record. The same Chicago company made yet other turntables with larger spindles that fit the others in that company's offering of odd-sized hole labels, Standard, Oxford and United.

As well, Canadian Berliner (Victor) discs, and I think some others, had a brass grommet around the centre hole until about 1904 or so; if I recall correctly, the players at this time had a nut, similar to the one on lantern battery terminals but larger, which fit the threaded centre spindle and locked the disc in place for playing.

There are two practical solutions. The first involves using a thick piece of light-weight cardboard that has a hole in the middle for the spindle and is cut to the size of a normal 10 or 12 inch record. Put the record on top of the cardboard on the turntable. For those of us with short spindles, the thickness of the cardboard should elevate the record to just above the spindle, allowing for the user to center the record manually. See if your turntable manufacturer or parts supplier offers a small spindle. It's worth the sound.

The other method involves removing the spindle from the turntable.

It's a shame many re-issuers don't care about centering their source material. Think of all the 78s that weren't played or sold because the spindle was off- center.

An interesting side note: I've seen several discs, usually Grey Gull products, which had either off-centre labels or labels which had moved (and thus torn) while being attached; these may have been the "slightly defective" records which were sold at a discount in mail order catalogs. Anyone know for sure?

Courtesy Mike Biel, Allen Sutton, Steven C. Barr and Gary Herzenstiel